FORGE PARTS

Shape parts forged

metalstrong industrial products

made of steel and various non-ferrous materials

we

deliver

COMPETENT ADVICE

HOHE QUALITÄT

FLEXIBILITY THROUGH WIDE SUPPLIER NETWORK

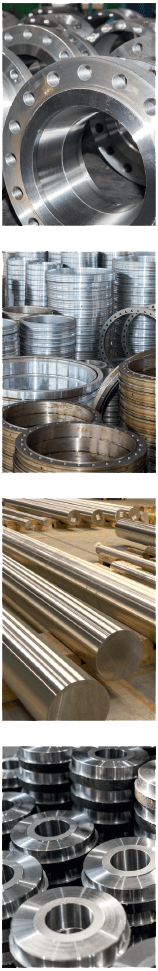

ROLLES RING PRODUCTS

seamless rolled rings, wheel tires, flanges & labyrinth rings: outer diameter from 200 to 7000 mm

Inside diameter min. 120 mm

Highe 30 up to 900 mm

Wieght 30 kg up to 25 Tonns

FORGE PRODUCTS

Applications: Rollers for cold and hot rolling mills Molded parts for apparatus construction, ship, turbine,Generator- and eccentric shafts, rods and spindles, Tooth wreaths and sprocket shafts for gearbox construction

Steel bars:

Length up to 15000 mm

Round:

Diameter 30 up to 1000 mm

Squares:

Side length 30 up to 1000 mm

Flat:

30×25 up to 2000×600 mm

Offset Shaft:

Diameter up to 2600 mm

Eccentric shaft:

Length up to 22000 mm

Axis:

Weight up to 170 Tons

Panes and perforated panes: Diameter up to 6500 mm

Weight up tp 170 Tons

Plate:

Length up to 6000 mm

Height up to 400 mm

Weight up tp 170 Tons

Bush:

Length up to 6000 mm

Height up to 400 mm

Weight up tp 170 Tons

Rings:

Diameter up to 7700 mm

Height up to 4000 mm

Weight up to 150 Tons

DIE FORGING PARTS

Applications: connecting rods, axle parts, drive parts and Piston rods for construction machinery, consumables, general machine parts, fitting parts

0,5 up to 10 kg from 300 Stk. Lot size

10 up to 500 kg from 50 Stk. Lot size

Maximum Diameter 650 mm

Maximum length 1800 mm

MATERIALS, HEAT TREATMENT, TESTING

Carbon steels, alloys, high-alloy and stainless steel grades as well as special alloys based on .B nickel or titanium and non-ferrous metals are available as a material according to international standards. Of course, heat treatment, testing and documentation can also be carried out according to standard or customer requirements.

MACHINING, PAINTING, ASSEMBLY

Turning, milling and drilling in the customer’s desired processing depth from pre-machined to the finished assembled product.

FORGE PARTS

Shape parts forged

metalstrong industrial products

made of steel and various non-ferrous materials

we

deliver

COMPETENT ADVICE

HOHE QUALITÄT

FLEXIBILITY THROUGH WIDE SUPPLIER NETWORK

rolled Rings

Running gears

Flanges

Labyrinth rings

ROLLES RING PRODUCTS

Outer Diameter von 200 up to 7000 mm

Inside Diamter min. 120 mm

Height 30 up to 900 mm

Weight 30 kg up to 25 Tons

FORGE PRODUCTS

Applications: Rollers for cold and hot rolling mills Molded parts for apparatus construction, ship, turbine,Generator- and eccentric shafts, rods and spindles, Tooth wreaths and sprocket shafts for gearbox construction

Steel bars

Round

Square

Flat

Offset Shaft

Eccentric shaft

Axis

Panes and

perforated panes

Plates

Length up to 15000 mm

Diameter 30 up to 1000 mm

Side lenght 30 up to 1000 mm

30×25 up to 2000×600 mm

Diameter up to 2600 mm

Lenght up to 22000 mm

Weight up tp 170 Tons

Diameter up to 6500 mm

Weight up tp 170 Tons

Lenght up to 6000 mm

Height up to 400 mm

Weight up tp 170 Tons

Bush

Lenght up to 6000 mm

Hight up to 400 mm

Weight up to 170 Tons

Rings

Diameters up to 7700 mm

Height up to 4000 mm

Weight up to 150 Tons

DIE FORGING PARTS

Applications: connecting rods, axle parts, drive parts and Piston rods for construction machinery, consumables, general machine parts, fitting parts

0,5 up to 10 kg from 300 Stk. Lot size

10 up to 500 kg from 50 Stk. Lot size

Maximum Diameter 650 mm

Maximum length 1800 mm

MATERIALS, HEAT TREATMENT, TESTING

Carbon steels, alloys, high-alloy and stainless steel grades as well as special alloys based on for example nickel or titanium and non-ferrous metals are available as a material according to international standards. Of course, heat treatment, testing and documentation can also be carried out according to standard or customer requirements.

MACHINING, PAINTING, ASSEMBLY

Turning, milling and drilling in the customer’s desired processing depth from pre-processed to the finished assembled product.

Talk with us!

We look forward to hearing from you and will get in touch with you in a timely manner.

Pinczolitsch GmbH

Gusswerkstraße 2

A-7051 Großhöflein

Phone

+43 (0) 2682 63631-0

info@pinczolitsch.at